Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?

Related knowledges

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades

Diamond Wire Saw For Reinforced Concrete Cutting

Product Features:

1. Customize different formula and guarantee performance cost according to the mixing percentage of hard, medium, soft( Determinants:content proportion of steel and concrete hardness ) all kinds reinforced concrete, in order to maximize the performance;

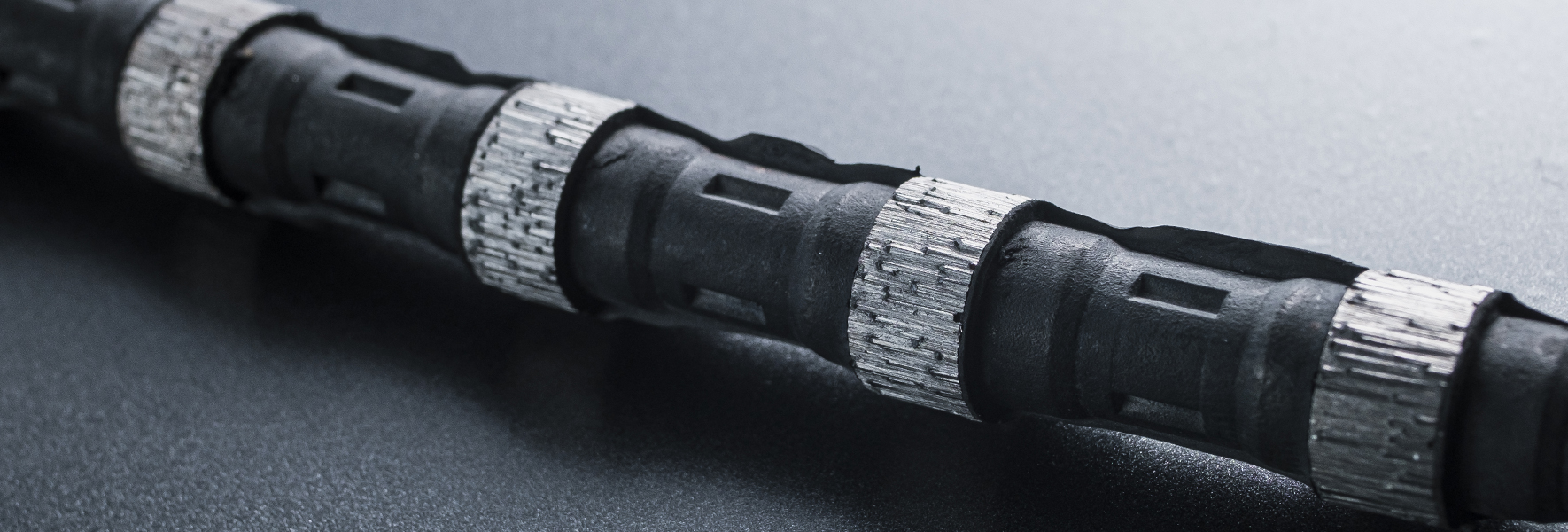

2. Fine selected diamond with great strength and toughness ensures the sharpening feature and lifetime of the diamond wire;

3. Sophisticated sintering technology with well controlled temperature and pressure guarantees the diamond beads with great anti-abrasiveness feature;

4. Mature injection technology and production technique makes sure the plastic enter into every gap of cable and holds the diamond beads with firmness;

5. Self-developed automatic production equipment and strict inline and final inspection controls the quality and stability.

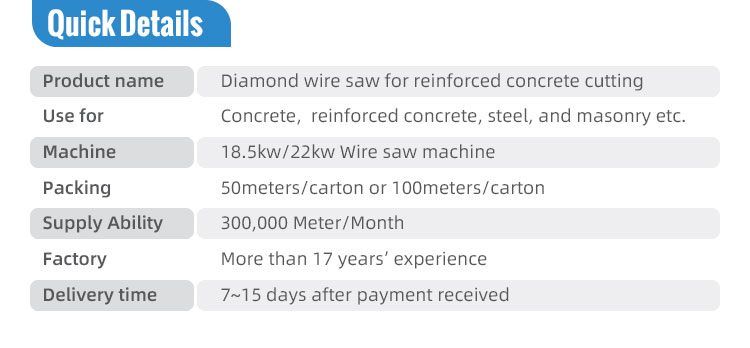

Product Specification:

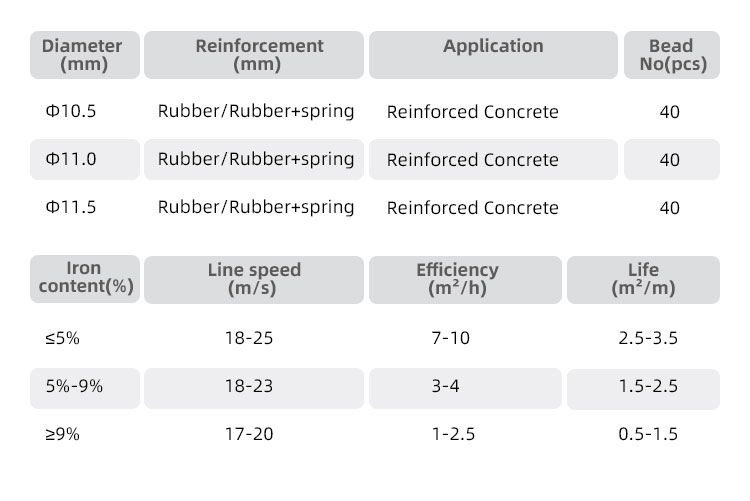

Diameter | Bead No. | Reinforcement | Usage |

| D10.5 | 40 | Rubber/Rubber | Reinforce Concrete |

| D11.0 | 40 | Rubber/Rubber | Reinforce Concrete |

| D11.5 | 40 | Rubber/Rubber | Reinforce Concrete |

| Cutting material | Line speed | Efficiency(m²/s) | Life(m²/m) |

| Class1-2 | 18-25 | 7-10 | 2.5-3.5 |

| Class3-4 | 18-23 | 3-4 | 1.5-2.5 |

| Class5 | 17-20 | 1-2.5 | 0.5-1.5 |

Other specifications are available upon request.