1. Introduction

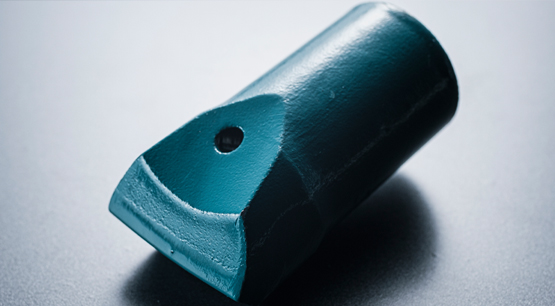

The diamond wire saw is a cutting tool that uses diamond particles as the cutting material, primarily employed in cutting concrete, stone, metals, and other hard materials. It is characterized by high cutting speed, precision, and a wide range of applications, making it an essential tool in modern construction, mining, and stone processing industries.

2. Product Features

High-Efficiency Cutting: The diamond particles in the wire saw have exceptional hardness and wear resistance, enabling fast cutting of various hard materials.

High Precision: The design and manufacturing process of the diamond wire saw ensure high precision cutting, resulting in smooth and flat cut surfaces.

Wide Applicability: Suitable for cutting a variety of materials, including concrete, granite, marble, and metals.

Easy Operation: The simple structure and user-friendly operation make it suitable for various on-site environments.

Eco-Friendly and Energy-Saving: The diamond wire saw produces less dust and noise during cutting, contributing to a better working environment.

3. Technical Specifications

Wire Diameter: Typically ranges from 6 to 11 millimeters, depending on the cutting requirements.

Cutting Speed: The wire speed generally ranges from 15 to 30 meters per second.

Cutting Depth: Varies with different models and configurations, reaching up to several meters.

Power Requirements: Common voltage is 380V, with power varying according to different models.

Cooling Method: Usually employs water cooling to reduce cutting temperature and extend the lifespan of the diamond particles.

4. Operating Steps

Preparation

Check the equipment and accessories for any damage or defects.

Ensure the power supply, cables, and cooling water source are properly connected.

Wear appropriate protective gear such as safety helmets, goggles, and gloves.

Installing the Diamond Wire Saw

Select the appropriate diamond wire saw based on the material and cutting requirements.

Install the wire saw on the guide wheels of the equipment, ensuring smooth operation on the wheels.

Adjust the tension of the wire saw to maintain proper tautness.

Testing the Equipment

Turn on the power and start the equipment, checking all functions for normal operation.

Adjust the cutting speed and pressure according to the specific situation.

Ensure the cooling system is functioning properly, providing adequate cooling water during cutting.

Cutting Process

Position the equipment near the material to be cut, ensuring good contact between the wire saw and the material surface.

Slowly start the equipment and begin cutting. Control the cutting speed and pressure to avoid excessive speed or pressure.

Monitor the cutting effect and the wear of the wire saw during the process, making necessary adjustments and maintenance.

Completion of Cutting

After completing the cutting, turn off the power and stop the equipment.

Remove the diamond wire saw and inspect it for wear, replacing it if necessary.

Clean the worksite, collecting the debris and dust produced during cutting to maintain a tidy work environment.

5. Precautions

Safety Operation

Operators must receive professional training before using the diamond wire saw, understanding the operation methods and safety precautions.

Protective gear must be worn during operation to prevent injuries from equipment malfunction or operational errors.

Avoid touching the rotating wire saw with hands or feet during cutting to prevent accidents.

Equipment Maintenance

Regularly check the wear of various parts of the equipment and replace or repair them as needed.

Keep the equipment clean and regularly remove the dust and debris produced during cutting.

Periodically check the cooling system's operation to ensure it functions correctly.

Operating Environment

The diamond wire saw is suitable for various cutting environments. However, in special conditions such as high temperature, high humidity, or flammable and explosive environments, appropriate safety measures should be taken.

Avoid using the equipment in extreme weather conditions like heavy rain or snow.

Storage and Transportation

Store the diamond wire saw in a dry, ventilated, and non-corrosive environment, avoiding prolonged exposure to sunlight.

During transportation, avoid severe vibrations and collisions to ensure the integrity of the equipment and wire saw.

6. Common Issues and Troubleshooting

Wire Saw Breakage

Cause: Excessive tension, severe wear, or quality issues.

Solution: Adjust the tension, replace severely worn wire saws regularly, and choose high-quality wire saw products.

Poor Cutting Performance

Cause: Inappropriate cutting speed or pressure, diamond particle loss, equipment malfunction.

Solution: Adjust the cutting speed and pressure, inspect and replace worn diamond wire saws, and repair equipment as necessary.

Abnormal Noise from Equipment

Cause: Worn parts, improper installation, or lack of lubrication.

Solution: Inspect and replace worn parts, reinstall components correctly, and lubricate the equipment regularly.

Cooling System Failure

Cause: Insufficient cooling fluid, blocked cooling pipes, or pump failure.

Solution: Check and refill the cooling fluid, clean the cooling pipes, and repair or replace the cooling pump.

7. Maintenance and Care

Daily Maintenance

Clean the equipment surface of dust and debris after each use.

Check the tightness of all connections to ensure no loose parts.

Regular Maintenance

Inspect the wear of the wire saw weekly and replace it as necessary.

Check the electrical and cooling systems monthly to ensure they are functioning properly.

Long-Term Maintenance

Conduct a comprehensive inspection and maintenance every six months, lubricating and tuning the equipment.

If the equipment is not used for an extended period, store it in a dry and ventilated place and perform periodic electrical maintenance.

8. Waste Disposal and Environmental Protection

Handling Cutting Waste

Collect and dispose of the waste produced during cutting according to environmental regulations.

Recycle metal waste when possible, and dispose of non-metal waste as per local guidelines.

Environmental Measures

Minimize dust and noise pollution during cutting by using enclosed cutting systems and noise reduction equipment.

Ensure the use and disposal of cooling fluids meet environmental standards to avoid environmental contamination.

9. Conclusion

As an efficient and precise cutting tool, the diamond wire saw is widely used in construction, mining, and stone processing industries. By following proper operation and maintenance procedures, users can maximize its superior performance, enhancing cutting efficiency and quality. This user manual aims to help users understand and operate the diamond wire saw correctly, ensuring its safe and stable operation.