At present, the base and diamond segment of the saw blade are almost always combined by high-frequency welding, because there are many types of high-frequency welding machines, and automatic welding machines are not within the scope of this article. This article mainly introduces manual welding of segments The process is also the simplest and most commonly used welding machine on the market at present, as an example, the description of segment welding.

High-frequency welding is also called high-frequency induction brazing. The principle is to use rapid heating to quickly melt the soldering lug sandwiched between the segment and the base, so as to achieve a tight connection between the segment and the base. This process usually lasts within 30 seconds. If the mechanical heating performance is faster, the welding process of 12-15 seconds is also very normal. So what exactly do you do in this seemingly simple process?

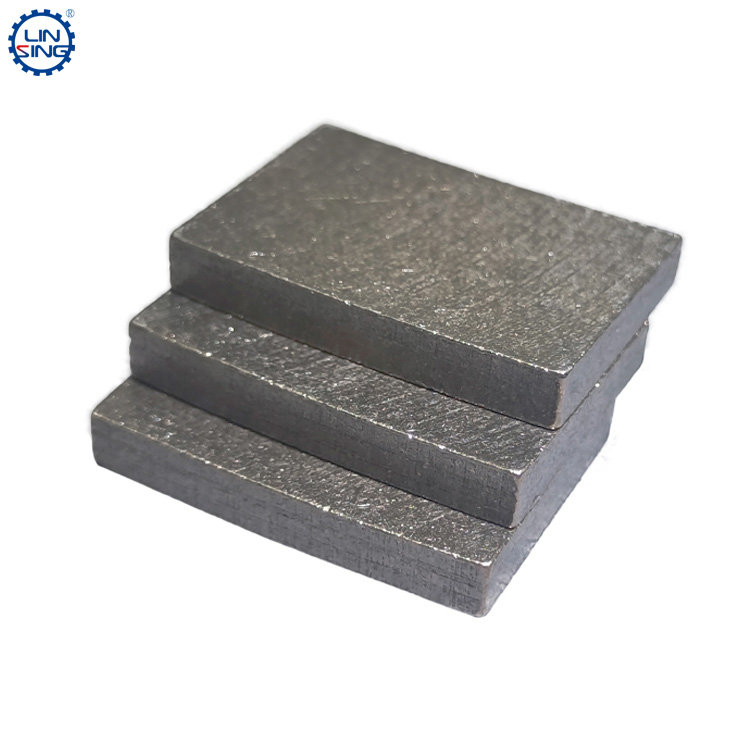

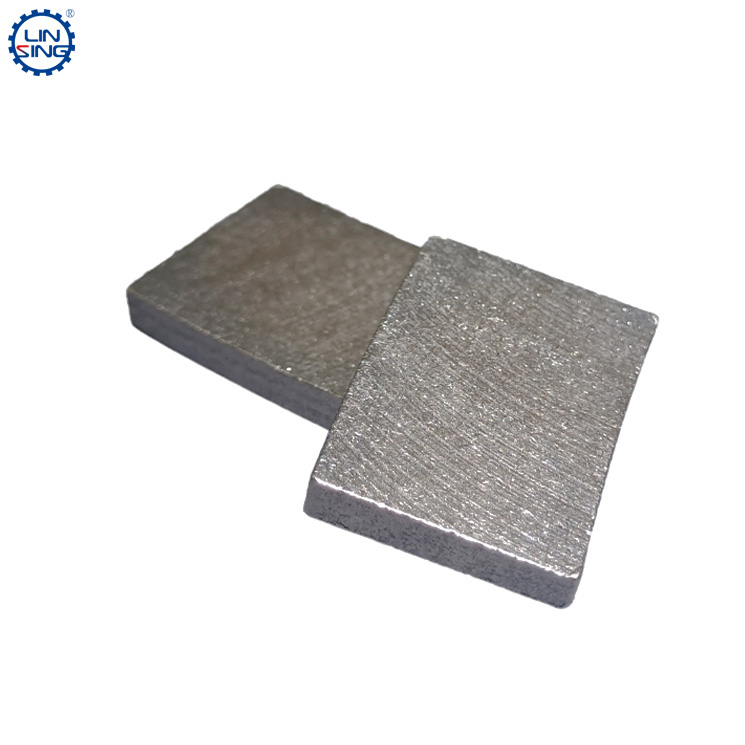

First, you need to clean the segment and base. If the base is a new purchase, just simply polish it. If it is an old base, you need to clean up the original segment and solder. First use high temperature to remove. If the removal is incomplete or there is Irregularities can be removed by grinding wheel or machining equipment. In terms of segment, the surface oxide layer is mainly removed, which can be polished with a grinding wheel or belt.

Secondly, because soldering lug is used in the soldering process, such as solder paste, it needs to be diluted. If the solder is copper soldering lug, borax needs to be added, which can have a good antioxidant effect. During the operation, apply these materials on both sides of the soldering lug to prepare for the upcoming welding process.

Then, during the welding process, try to adjust the high-frequency welding machine to rapid heating. The rapid and sudden heating can minimize the changes in the chemical composition of the diamond and the bond in the segment, and ensure that the soldering lug can quickly melt It also needs to ensure that once it melts, it quickly leaves the high temperature state. During the whole process, the segments need to be kept consistent in height and aligned left and right, so they need to be completed in a fixed mold, and the welding part will be tested through the mold later to fix the saw blade segment in a unified position.

Then, we need to adjust the welding strength of the diamond segment. There are two main steps. First, set the saw blade on the central axis of the same specification, and press the cover plate on the saw blade ( Fixture); 2. Clamp the torque wrench to the segment to be inspected, hold the handle with your right hand, and pull it upward or downward until the dial indicator reaches the specified reading; if the tooth does not fall, the segment weld meets the requirements. If the tooth is lost, it means that the segment does not meet the requirements and needs to be broken and re-welded.

Finally, after the saw blade has gone through the above steps, the welding process has been completed, so that it can be edged and stone cut.

Diamond segment high frequency welding instructions

Publish date:2022-07-06 17:57:34 Article From:Linxing Diamond Tools Clicks: