The diamond segment is composed of two parts: diamond and metal powder. The diamond segment is mainly granular, not powdery, and its composition is not a metal material, so we generally take diamond separately.

The most basic application of segment metal powder is elemental powder. People use common metal powders such as copper, iron, tin, zinc, nickel, cobalt, tungsten, titanium, and lead, and each element is elemental powder. The powder is mixed and stirred in a certain proportion to form a mixed powder. These are the most basic diamond powder formation process. This is the early diamond segment production method, but at present, people will add metal powder Some tungsten carbide, and polymer single crystal materials, such non-metallic elements are added to make the material of the segment binder harder, and the wear resistance is also improved, so as to match harder diamond powder to improve cutting performance and life.

Elemental powder involves the mixing process, but physical mixing cannot completely mix the powder, so it will cause the segment product to be unstable. This is very easy to occur when the mixing time is not enough. And with the time of the stirring and cold pressing process, the metal element will continue to precipitate, resulting in uneven product mixing. If the product is not uniformly mixed, the quality of the segment will naturally be unstable.

In order to solve this problem, prefabricated alloy powder was born. The manufacturing method of prefabricated alloy powder is divided into atomization method and hydrometallurgical method. The pre-alloyed powder high-pressure atomization method is pre-prepared with metal bond powders. Before sintering, metals of various components are smelted into alloys, and then atomized and sprayed to obtain metal bond powders with the required particle size. The metal bond powder processed in this way is very fine and the mixing is more uniform. The hydrometallurgical method is to dissolve metal ions in water, and the different element metals in the alloy are mixed in the solution according to the correct ratio to form a metal salt, and then precipitate and reduce to obtain a very fine metal alloy powder.

The prefabricated alloy powder solves the problem of unstable product quality caused by uneven mixing of the metal bond powder, and in the later diamond sintering process, because the metal elements have formed a stable structure, it can be carried out at a relatively low temperature Sintering, and the heat preservation and pressure holding time are also shortened a lot. Of course, alloy powder also has its own problems, such as the need to add additives for product fusion, which increases production costs, and during the process of making alloy powder, if the material ratio is wrong, all materials will be scrapped. In addition, alloy powders have higher barriers for diamond segment production, more processes, and other problems, which lead to higher material costs. Therefore, at present, metal powders are mainly simple powders. Diamond segment instability is alleviated by long-term mixing, small batch mixing and speeding up the production process.

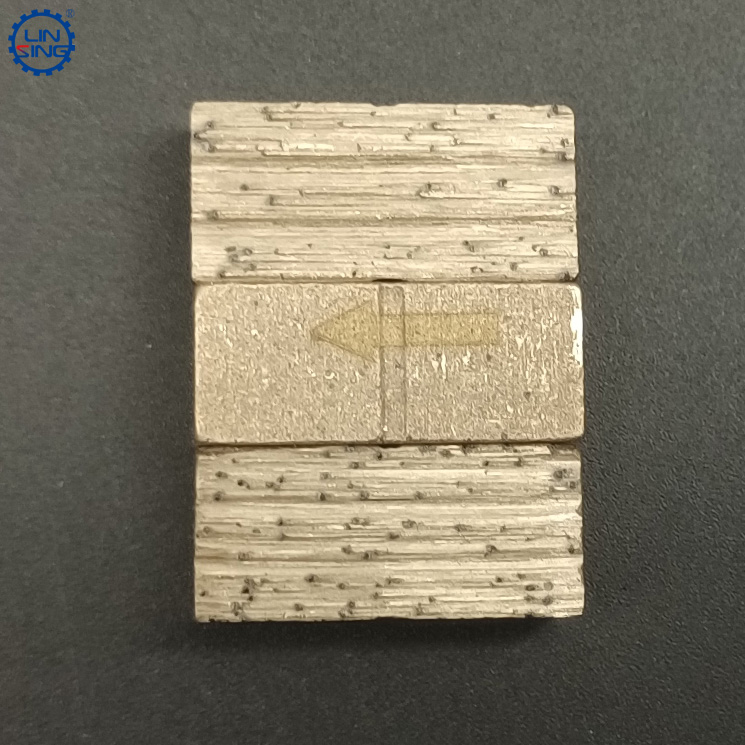

Diamond segment powder

Publish date:2022-07-06 17:28:48 Article From:Linsing Diamond Tools Clicks:

Related News

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- Why does the diamond segment not cut the stone? Over-carbonization is one of the reasons

- How to choose diamond powder for diamond segment

- How to calculate the content of diamond in the diamond segment

- Guidelines for the design of metal binds in diamond segments