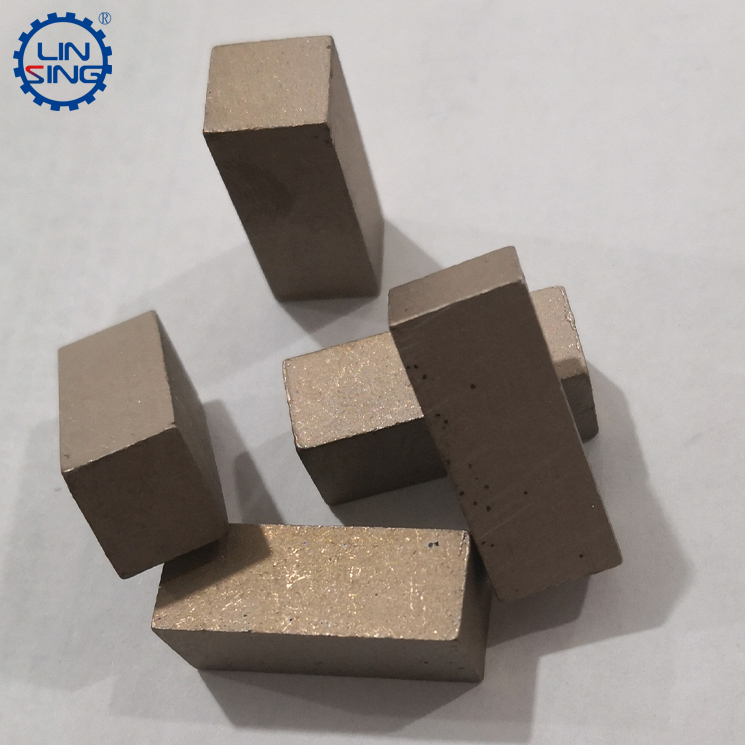

Jiangxi Linxing Diamond Tools Co., Ltd. is a manufacturer specializing in the production of diamond segments. In the course of nearly 20 years of research and production, five factors affecting the quality of diamond segments have been discovered. Let us understand below:

1. Dimensions:

After the diamond segment is sintered, the segment inspector of Linxing will always take a vernier caliper for random inspection. The length, width and height must be as same as the design size. The size also reflects the quality of the segment and the quality of the sintering process. After accurately calculating the appropriate ratio of the diamond segment, under the correct sintering process conditions, the segment size is only allowed to have a deviation of 0.1mm. For example, if 5000 segments of 3027 are produced today, the ingredients are proportioned according to the ingredients of 5010. When the segment is sintered, 5005-5015 segments will be produced. The closer to 5010, the larger the size of the segment. Accurate, the segment will not have the problem of too large and small size.

2: Density and weight

Similar to the detection of size, in the segment production process, the weight will be tested at different stages, from ingredients, cold pressing, to the finished product after hot pressing, each link must be tested for weight, because we tested the segment in the first part With the weight, we can calculate the density of the segment, and density is a very important part of the segment, which determines the density of the segment product. The higher the density, the higher the stability and life of the segment, and the higher the density For low segments, life span and quality must be relatively poor. Therefore, both density and weight can determine the quality of the segment.

3: Structure

The structure of the segment largely determines its advantages and disadvantages. For example, when the structure of the segment is integrally formed, the segment life will be relatively longer. Of course, the disadvantage is that the increase in the cutting surface causes the sharpness to decrease. The sandwich segment is different. Because the non-working layer does not participate in the cutting, the sandwich segment is quickly ground and concave. Due to the drastic reduction of the working area, the cutting performance of the segment is increased, but the service life will be shortened. Generally speaking, the more layers The better the sharpness of the segment, but the lifetime will continue to decrease.

4: Diamond powder

Diamond powder is divided into grade, particle size, and hardness. The higher the grade of diamond, the faster the blade can be produced during the cutting process, and the grinding ability is stronger, while the diamond with larger particle size has more continuous cutting ability. Hard stone has a strong crushing ability, and the hardness determines the grinding ability of the diamond, so a good diamond segment can clearly see the diamond crystal particles on the segment surface, and an obvious diamond tailing effect is formed during the cutting process.

5: Proportion of metal powder

Diamond is fixed with metal powder through solid phase and liquid phase. A good diamond segment, diamond and metal powder are firmly combined to form a physical and chemical holding force, thus having a higher cutting performance, so In the cutting process, you must be concerned about the holding ability of the metal carcass binder. The simple test method is to measure the segment thickness after cutting a certain amount of stone. According to the consumption capacity, it is used to judge the quality of the carcass binder.

Five factors affecting the quality of diamond segment

Publish date:2022-07-07 17:42:45 Article From:Linsing Diamond Tools Clicks: