Diamond saw blades often encounter a situation in the process of cutting stone, that is, the sharpness of the segment is not enough during the cutting process, which is mainly reflected in the slow cutting of the knife and the normal movement of the knife when maintaining a certain mechanical speed. High speed, the diamond segment consumes too fast, and the cutting efficiency cannot be increased. The main reason for this situation is the problem of the diamond segment formula. How to make the sharpness of such a segment design higher?

From the cutting process, we can see that the bond strength in the diamond segment should be consistent with the diamond wear rate. If the bond strength is too soft, the diamond segment will wear out faster during the cutting process, and the diamond will be exposed very quickly. It falls off prematurely without being fully functional, resulting in average diamond segment efficiency but shortened lifespan. But if the bond wears slowly, then the diamond exposure is less, the cutting is slower, and the metal bond consumption is less than the diamond consumption. In this case, the saw blade will not move, which is what we started talking about the problem of low diamond segment cutting efficiency.

Generally, there are four solutions to this situation, which can significantly improve the sharpness of the segment:

First: increase the concentration of diamond, because the obvious manifestation of the inability to move is that the diamond is not exposed enough. In order to increase the exposure of diamonds, increasing the concentration of diamonds can properly solve the problem. It is very important to keep the diamonds in the segment high at all times. But this kind of improvement method will increase the consumption of diamond powder, in simple terms, increase the material cost of the segment. And the concentration of diamond cannot be increased too high, too high concentration will reduce the holding power of the segment's metal bond, causing the diamond to fall off.

Second: Slightly reduce the content of cobalt and tungsten in the diamond bond. The advantage of this is to reduce the hardness of the metal bond and allow the diamond powder to be better exposed. The disadvantage is that this method will reduce the life of the segment and may cause segment instability.

Third: increase the size and concentration of diamond to further increase the strength of the metal bond. This method is mostly used in foreign diamond segments. Increasing the size of the diamond can increase the exposure of the diamond, and increasing the metal bond is better with large-grain diamonds. The granularity matches. If the size of the diamond is simply increased, it is very likely that the holding force will be insufficient, causing the diamond to fall off.

Fourth: The use of layered segments, by increasing the non-working layer and increasing the cutting pressure, this process has also been recognized and applied by the most people. In the non-working layer, iron flakes or alloy powder layers can be added to form a waterway. It is convenient for chip removal, and also allows the segment to cool more quickly, which increases the cutting efficiency while ensuring the cutting life.

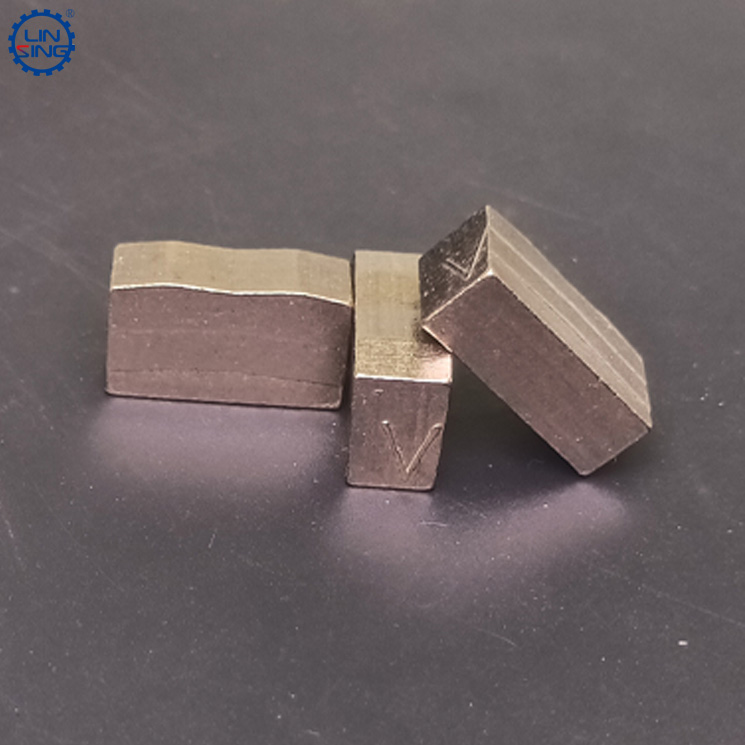

Formula adjustment of high sharpness diamond segment

Publish date:2022-07-06 17:24:27 Article From:Linsing Diamond Tools Clicks: