Diamond wire saw is a diamond tool used to cut stones of various hardness. It can also be used for cutting reinforced concrete. During use, it is affected by the site, machinery, and processing conditions, and the wire saw is also affected by its own quality. Or the influence of operator's misoperation.

There are two types of rope breaks. The first type is partial breakage of the joint. This situation is caused by the broken joint of the wire saw or a problem with the fixed wire saw. The wire ropes on both sides come out of the joint. The main reason for this is that the joint is not tightly crimped or crimped too tightly.

The second situation is that there is a broken rope in the part other than the joint. This situation is mainly caused by the following reasons. We will introduce and analyze one by one, and give corresponding solutions.

1: The quality of the wire rope causes the wire saw to break

The wire rope is an important part of the diamond wire saw. It bears the main pulling force of the motor. If the quality of the wire rope is poor, the wire rope is prone to fatigue and fracture under long-term high-strength tension, especially for the wire rope with weak tensile strength. It is particularly prone to break the rope.

Solution: Need to replace a better wire rope, and in terms of weaving rope, try to achieve multi-strand winding. If we can change the spiral braiding method to a tighter fancy braiding method, it will make the wire saw The tensile strength has been improved to a certain extent.

2: Speed is too fast

During the cutting process of the wire saw, if the cutting speed is too fast, the pulling force received during the cutting process will increase, especially in the process of cutting some very hard materials, the huge friction will cause the beads to loosen. After the beads are loosened, the beads will not participate in the cutting process. Instead, they will continue to wear the wire rope inside the wire saw. As the beads become more and more loose, the wire rope wears rapidly, and eventually the wire rope at the beads breaks. It is common, and as the wire rope breaks, the loose beads fly out of the wire saw at high speed, like a bullet. Once they hit a person, a serious construction accident will occur.

Solution: The diamond wire saw cutting process must be stable, not just fast, choose the appropriate cutting speed, and match different wire saw products (Linxing diamond wire saw includes life type, sharp type, comprehensive type and other products, can meet The cutting needs of different customers). And it must be checked after the wire saw is used up. Once the beads are loose, the beads need to be broken immediately. If the wear has occurred, it is best to perform the operation process of disconnecting the rope and reconnecting.

3: The beads are not firmly fixed

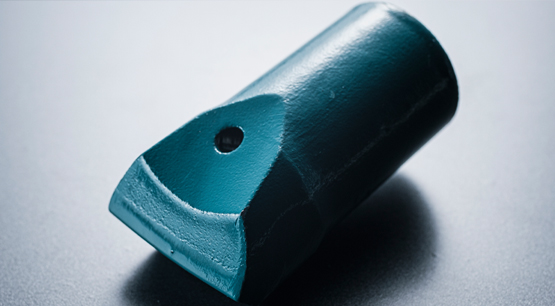

Beads are connected by rubber, plastic or spring. If the glue injection & injection molding process is not good, it is easy to loose the beads. This situation is mainly caused by unqualified raw materials.

Solution: This situation occurs in many small wire saw factories. Because there is no core injection and glue injection process, only the ordinary process is used to complete the wire saw connection, and the loosening of the beads is unavoidable. It is recommended to choose a large factory The wire saw will be more secure in terms of quality and after-sales.

4: Mechanical problems

If the wire saw motor is aging or damaged, it will cause the wire saw to run unsteadily, especially in the case of frequent jitter. Many factories do not care about it. Long-term use of this machine will increase the load on the wire saw, and the uneven force will cause the wire rope to endure Large pulling force causes the steel wire rope to break directly.

Solution: Replace the high precision, allow a more stable wire saw machine, and do a good job of long-term maintenance

5: Flywheel angle problem

During the cutting process of the wire saw, if there is a problem with the angle of the flywheel, the wire saw will bear more torsion during the cutting process. If allowed, it will consume too fast and the current will be too large. Long-term cutting will cause problems. As a result, the wire saw eventually broke the rope.

Solution: Reasonably adjust the angle of the flywheel so that the flywheel and the cutting surface are perpendicular to ensure that the wire saw can cut better and more steadily.

6: Wire saw storage causes the rope to break

Wire saws have special storage requirements. First of all, rubber ropes cannot be stored at a low temperature. Under low temperature conditions, the rubber on the fixed part of the wire saw will quickly age, and it will not protect the wire rope at all during cutting. Wire saws cannot be parked for a long time. Because wire saws use cooling water during the cutting process, if it is an injection molded rope, the water will continuously penetrate into the wire rope. If it is parked for a long time, the wire rope will rust, which will cause breakage.

Solution: If you want to save the wire saw in a low temperature environment, you need to increase the storage temperature. Once the wire saw is used, especially the wire saw that has been in contact with water, it should be used within half a year as much as possible.

7: Wire saw distortion is too high

Although wire saw is a flexible cutting tool, it can be bent appropriately, but once the bending angle is excessive, especially when mining is cut to the final stage, or the steel concrete is cut to the final stage, the wire saw is prone to distortion at this time If it is too high, this will easily cause the connection between the rubber and the beads to crack directly, and then the beads will also loosen, which will eventually cause the rope to break.

Solution: At the end of cutting, an old wire saw can be replaced to complete the final cutting, which can save the wire saw to the greatest extent, and can also let the discarded wire saw use its final waste heat.

8: The amount of cutting is too large

Excessive amount of knife will directly increase the cutting resistance, and it is prone to excessively high wire saw distortion.

Solution: Reduce the amount of cutting to keep the wire saw cutting at a normal angle.

In general, diamond wire saws will encounter many problems during the cutting process, but rope breakage is the most dangerous and must be avoided. Therefore, in the wire saw cutting process, you must carefully observe, inspect and investigate carefully. , Don’t be afraid of troubles, and then you can achieve safe construction