Diamond segment in the working process, exposed diamond through its hardness advantages, the stone polishing, more hard diamond powder will continue to polish the stone, slowly through such polishing, so that the stone is cut apart. This is the basic principle of diamond segment processing stone. In the process of working, diamond although very hard, long-term rapid cutting, it will inevitably produce loss; diamond loss mainly has two parts: grinding part of natural wear, which is natural wear is inevitable wear, the second point is diamond grinding process, too much force, resulting in diamond fall off, this is the processing process sawing line speed adjustment too fast caused, can be resolved.

In addition to the above-mentioned reasons, in the diamond segment design and production process, there are many ways to increase the life of the diamond segment. Below, we will be based on a Lin Xing modified a life-type segment case analysis, so that everyone clearly understands the impact of the segment life of all links.

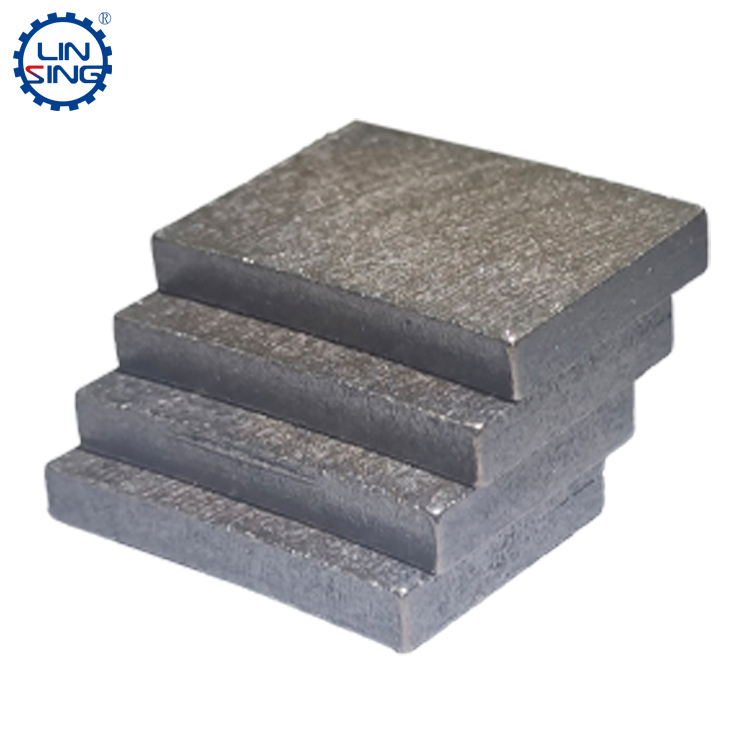

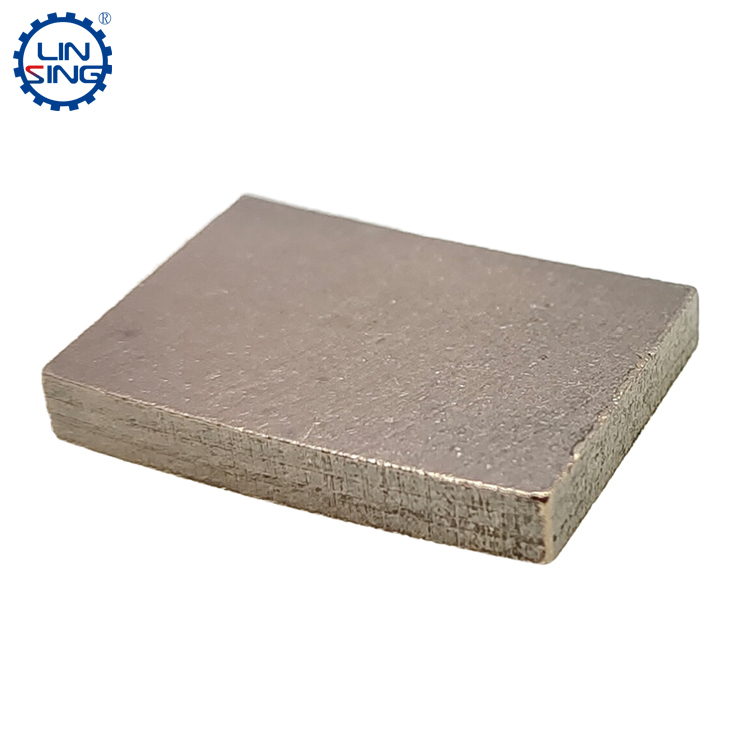

This customer is a distributor in Hyderabad India, year-on-year procurement of our 3203 this formula, is a general-purpose strong formula, shaped as a cuboid seven-layer structure. Which size from 900-3500mm saw blades have, cutting objects are mainly used for cutting, for granite cutting effect is better, can also be used for marble can also be cut, but marble cutting effect is not prominent, can only be counted as ordinary. Customers are very satisfied with the cutting efficiency of this segment, this year, the customer asked whether the current cutting efficiency can be properly increased in the case of the life of the segment. Lin Xing in line with the customer-based business philosophy, from the process to make the following improvements:

Usually the easiest way to increase life. The most common way to improve is to increase the grade of diamond powder or improve the strength of the binder, so that diamond is less likely to fall off, but will increase a lot of costs, which is in conflict with customer requirements, so based on the above situation, we change the structure of the segment follow:

The original straight cuboid block was changed to a three-layer transition layer. Straight rectangular blocks will be relatively weak impact resistance, in order to increase the impact resistance of diamond, the design of three layers of stress transition layer can better alleviate this situation, but also allow diamond to reduce the risk of falling off.

The structure of the previous seven layers of mezzanine changed to five layers, and the width of the non-working layer was widened. Although the seven layers of mezzanine segment to ensure the sharpness of the segment, but the cutting surface is too dispersed, resulting in the segment holding force is not enough, so changed to five layers later, the pressure area of the work layer is larger, the life of the segment will be longer.

After the above simple changes, at present, the life of the segment increased by about 10%, the current customer is very satisfied with the segment. Of course, the above is only the improvement of the formula, in the actual application process, even if it is the same segment, good operation, can also increase the life of the segment. Let's take a look at this: Speed: Diamond segment in the process of cutting stone, the faster the blade swing, the faster the cutting efficiency, and the slower the speed of the turn, the slower the cutting efficiency is naturally slower. Therefore, the corresponding cutting speed is generally matched. Diamond segment if the use of fast speed, then the efficiency will be improved, but the life of the segment will be reduced.

Line speed (segment speed): According to the different stone cutting machinery, the cutting process provides different wire speed, in general, the segment speed is slow, the cutting process, diamond wear is minimal, the disadvantage is low efficiency, and may appear the segment is flattened and the situation of cutting stone.

Then a reasonable set line speed is also very normal, if in the course of operation, according to the material, you can adjust the appropriate line speed, diamond segment life will be greatly improved. In particular, combined with speed to set the line speed, to ensure that the segment in a stable long-term cutting state, the life of the segment is very important.

Segment speed (segment speed), saw blade in the processing of stone, segment speed is also very worthy of study, the faster the segment speed, the faster the segment consumption, it is very affected the life of the segment, especially marble, if the excessive speed of the segment will not only reduce the life of the segment, but also reduce the efficiency of cutting.

In general, how to improve the service life of diamond segment is the result of joint efforts of segment manufacturers, stone processing manufacturers, as well as welding processing workshops and other parties.

How to improve the working life of diamond segments?

Publish date:2022-07-06 19:51:24 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades