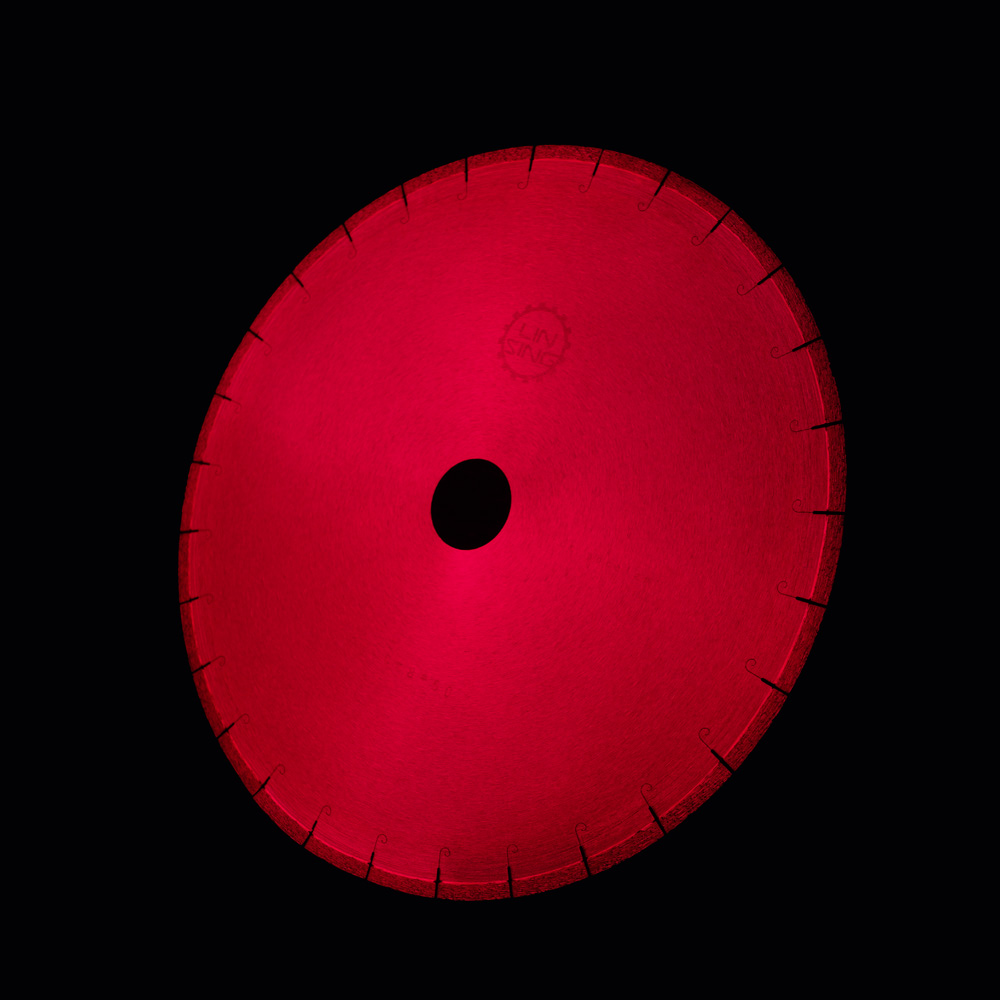

High-quality diamond saw blade has the following characteristics, let us specifically learn below:

1: High wear resistance;

High wear resistance represents that the diamond saw blade has higher wear resistance in the stone-cutting process. The process of cutting stone with a saw blade is itself a process of friction between the stone and the cutting segment. Its wear resistance determines the life of diamond segment. Especially in some markets where the competition of diamond saw blade products is relatively fierce, the cutting life is short and the cost of stone production is also low. 2: High sharpness;

2: High sharpness;

High-quality diamond saw blade sharpness is higher than regular saw blade in the stone cutting process. The main reason is that the diamond proportion and metal bond powder of the diamond segment on the diamond saw blade has more robust applicability. The sharpness of the saw blade is not absolute concept. Because it has different cutting performance when cutting different stones or certain cutting objects, with strong cutting ability and fast cutting speed. High-quality saw blades all have such characteristics. A saw blade with higher sharpness can greatly increase the cutting speed, improve the cutting ability and reduce the cutting cost.

3: Stable feeding speed;

When the diamond saw blade cuts stone, if the saw blade cuts smoothly, the feeding speed will remain in a stable state, and the feeding situation will relatively stable. The material of the high-quality saw blade is stable, the flatness of the blank blade is kept at a high level, and the values of end jump and radial jump are kept at a low level, so the feeding speed will naturally move smoothly.

4: Resistant segment does not deform under high temperature

The high-quality diamond segment can be more heat resistant, because the material of the blank blade has more alloy material, the bond stability ability is higher, so the high-temperature resistance will be higher in the cutting process.

5: The blank blade does not deform

The high-quality diamond saw blade blank blade is not easy to be deformed. During the cutting process, the rigidity and toughness of the blank blade are greatly improved, and the cutting ability will also be improved.

6: Weld firmly

High-quality diamond saw blades have high firmness and high welding strength, and there will be no tooth loss during the cutting process.

7: Low noise

High-quality diamond saw blades will be silenced, and the silenced saw blades will have lower noise. Not only that, but often the silent blades have higher cutting efficiency.

8: Cut without chipping

High-quality diamond saw blades will not chip during the cutting process. However, the teeth of the saw blade need to be replaced according to different cutting materials. 9: Smooth cut

9: Smooth cut

The cut of a high-quality diamond saw blade must be smooth, and this state can show that the saw blade is in a normal working state.

Nine characteristics of high-quality diamond saw blades

Publish date:2022-12-05 11:29:50 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?