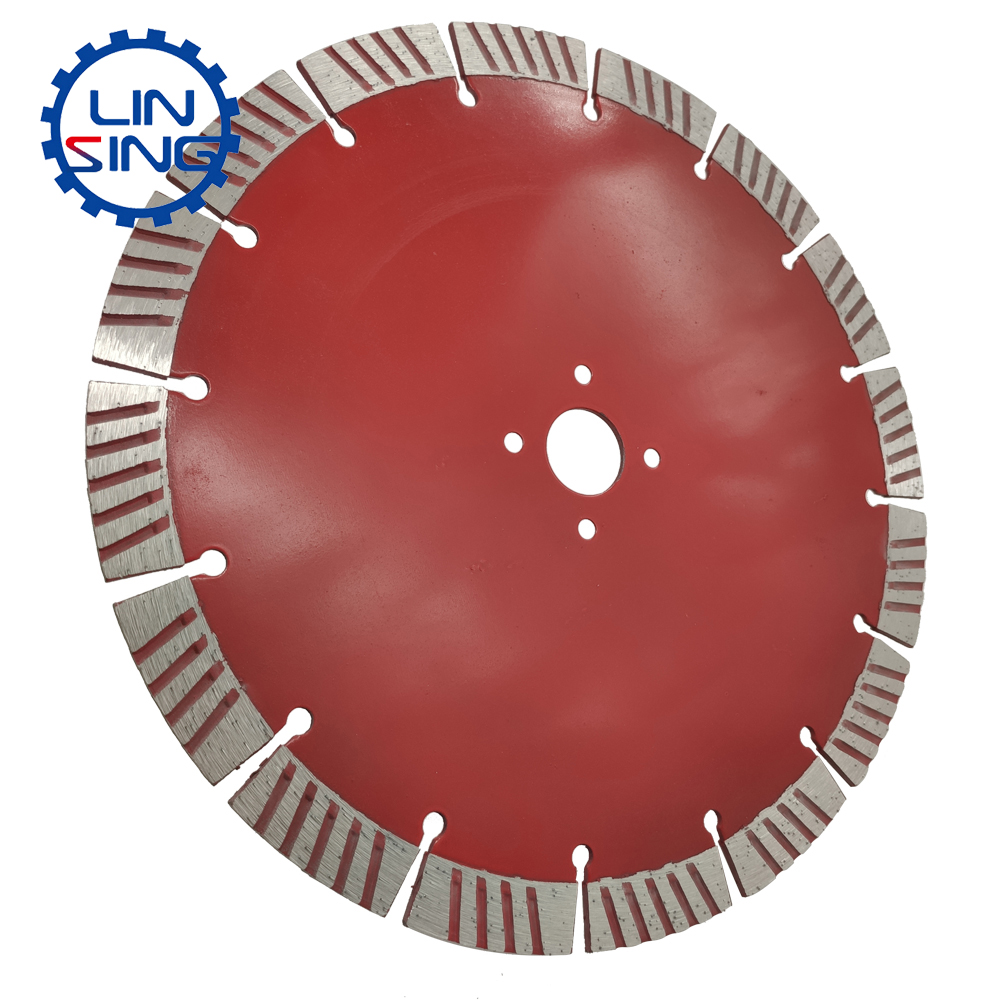

Small-diameter diamond saw blades (diamond disc) can be used for cutting hard and brittle materials such as marble, granite, concrete, refractory materials, and ceramics. Some cutting blades are also used for stone carving and slotting and grinding. In terms of cutting equipment, it is generally a portable cutting machine and an angle grinder. Some products are also used in table saws, such as vitrified tile saw blades, ceramic tiles and some fragile stones. This article mainly introduces 6 points that need to be paid attention to during the use of diamond disc. 1. In terms of detection: since diamond discs are widely used in hand-held cutting machines, the safety factor is low during use, especially for the structural firmness of the diamond saw blade and the diamond segment. Before use, it is necessary to inspect the blade body and the cutter head of the saw blade. The inspection items are as follows:

1. In terms of detection: since diamond discs are widely used in hand-held cutting machines, the safety factor is low during use, especially for the structural firmness of the diamond saw blade and the diamond segment. Before use, it is necessary to inspect the blade body and the cutter head of the saw blade. The inspection items are as follows:

1) . Damage inspection: mainly observe with the naked eye whether the saw blade is broken, broken or has faint cracks. If such a situation occurs, this type of saw blade must not be used on the machine. In addition to the problems of the saw blade, the wear of the main bearing, bushing and flange of the cutting machine also needs to be judged, and the severely worn or damaged parts should be replaced.

2) . Bending inspection: it mainly refers to the fact that the saw blade is distorted due to unreasonable placement or cutting problems. This type of saw blade has a huge impact on the cutting surface and is potentially dangerous. This type of saw blade has a huge impact on the cutting surface and is potentially dangerous, so it is best to mechanically twist or directly replace this type of saw blade according to the situation.

3). Slice structure selection: generally, users will choose a variety of different types when using diamond discs, such as corrugated teeth, dry cutting teeth, continuous teeth or other types of saw blades, according to the cutting material and cutting requirements. For selection, such as ceramic cutting, continuous teeth should be used as much as possible, and dry cutting teeth can be used for concrete cutting and demolition. Different cutting materials and cutting requirements correspond to different diamond discs.

Selection of special sheet: in the process of cutting materials, in order to increase the safety or to increase the cutting line speed, in many cases, thickening the sheet to make the sheet thicker can significantly improve this problem. However, the disadvantages brought about are also very obvious, that is, the thickness of the chip body increases, and the thickness of the cutter head will also increase accordingly, which increases some cutting costs and waste of cutting materials.

2: Protection: protection is a very important part. General protective measures include full-body protection, including helmet, protective glasses, protective masks, protective earmuffs to reduce noise, first sets of labor insurance, insulated protective shoes, etc. It is a protective gear that must be used during the cutting process of cutting discs.

In addition to the protection of the appearance, during the cutting process, people should try to be behind the protective cover, that is, stand directly behind the cutting body, and the order of cutting is the person, the cutting machine, and the cutting object.

3: Preparation before cutting: install the diamond discs according to the direction of the arrow, so that cutting along the edge of the saw blade can speed up the cutting efficiency and increase the cutting life, and strictly follow the operating instructions during the installation process. Finally, the flange needs to be tightened so that the saw blade is in a good fixed environment mechanically. It can be tested for a period of time, and finally it is confirmed that the small diamond discs are well fixed. During the fixing process, it is also necessary to pay attention to the problems of oil and rust. The oil stains should be wiped clean, and the rust is best removed to prevent the saw blade from sliding or not being firmly fixed during the cutting process.

4: Precautions during wet cutting: In the process of cutting with water, the amount of water is very important. If the amount of water is too large, there will be slippage during the cutting process, which will reduce the cutting efficiency. However, if the amount of water is insufficient, it is easy to burn the diamond segment Happening. Therefore, in order to perform better cutting, it can be judged according to the mud and sound, if the mud is turbid and the normal cutting noise is judged, on the contrary, if the cooling water is too clear, it means that there is a problem with the cutting.

5: Precautions in the dry cutting process: dry cutting is not impossible for wet cutting, and the effect of adding water to dry cutting will be better, but since dry cutting is also sintered after all, the diamond segment temperature exceeds the sintering temperature, and the diamond segment will soften Therefore, it is necessary to keep the saw blade for a few seconds of rest time during the cutting process. Generally speaking, the more rest time, the stronger the cutting ability, and vice versa, the weaker the cutting ability. 6: Troubleshooting: various faults may occur during the cutting process of the saw blade, such as excessive cutting noise, severe shaking of the saw blade, difficulty in cutting the saw blade during cutting, and difficulty in sawing. Sometimes there may be cutting problems. It is very necessary to stop the machine for inspection, and find solutions according to different problems.

6: Troubleshooting: various faults may occur during the cutting process of the saw blade, such as excessive cutting noise, severe shaking of the saw blade, difficulty in cutting the saw blade during cutting, and difficulty in sawing. Sometimes there may be cutting problems. It is very necessary to stop the machine for inspection, and find solutions according to different problems.

Precautions during the use of diamond disc

Publish date:2022-12-05 09:11:15 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?