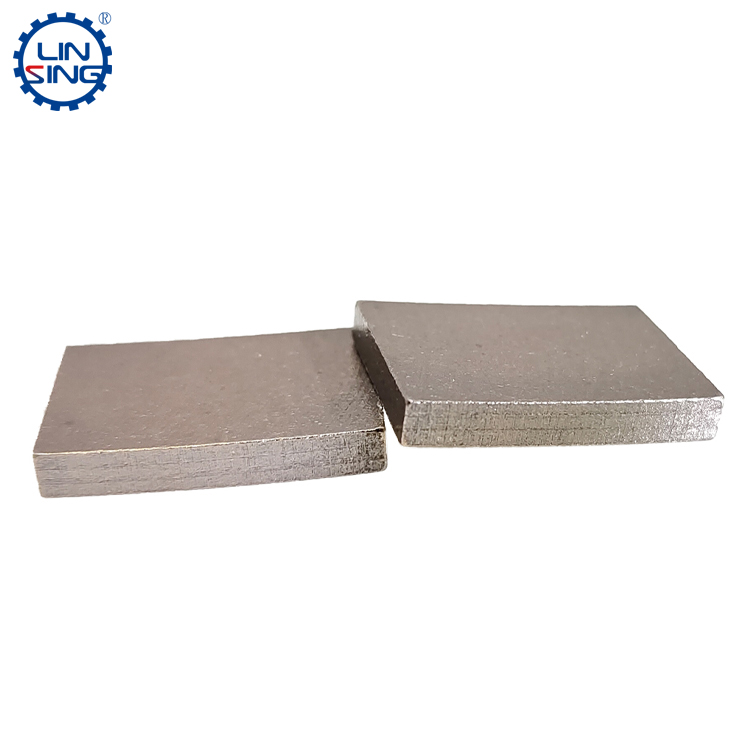

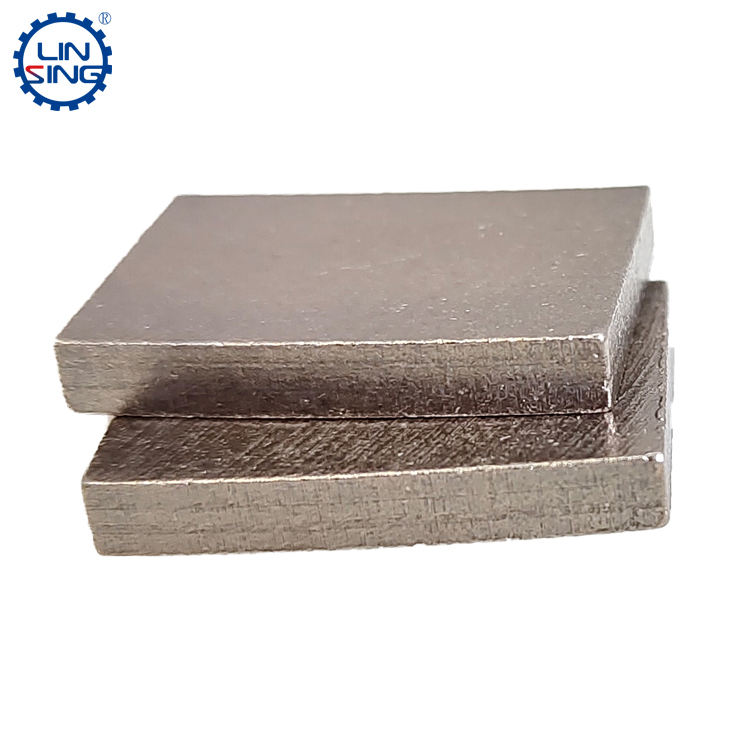

In the process of cutting stone blocks with a saw blade, especially for medium and large saw blades with a diameter of more than 900 mm, the front end of the blade is naturally worn during normal cutting, the upper part of the blade is obviously worn, and the lower part is only slightly worn. However, in the actual processing process, the segment will show abnormal cutting shape, such as the segment is wide at the top and narrow at the bottom, or the left and right sides of the segment are severely worn and the other side is slightly worn; or cutting occurs the front part of the tooth is severely worn, while the rear side is slightly worn. These indicate that the use of the saw blade and the diamond segment is problematic. In professional terms, it is called the segment eccentric wear, which means the segment is working under abnormal conditions, and it need to be adjusted in time.

So what is the reason for the eccentric wear of the segement? Is there any solution? Below we will explain the various eccentric wear situations one by one.

The partial wear of the segment is wide at the top and narrow at the bottom. It is generally caused by problems in the mixing process of the segment during the production process and insufficient hardness of the lower binder material; it may also be caused by the temperature of the overall segemnt during the sintering process. There are problems in control, and the lower sintering temperature is not up to standard; or the segment’s manufacturer uses diamond mixing to reduce costs, and the side uses poor quality diamonds, which will also occur. This kind of situation is relatively rare at present, especially for Linxing diamond segments, such problems will never occur. This kind of problem indicates that the quality of the segment is extremely poor. It is recommended that the manufacturer replace the segment manufacturer.

The left and right sides of the segment are worn sideways. This situation is very common, and it is generally caused by the following situations:

1: The diamond concentration of the segment is too low are resulting in easy wear on the side of the segement. This situation is also a problem of the quality of the diamond segment. Properly increasing the diamond concentration can solve this problem.

2: The saw blade substrate is bent or deformed, especially the serrated part. If there is deformation, the cutter head will naturally wear on one side during the cutting process. If you encounter such problems, you can either repair the matrix or replace it with a new one.

3: The diamond matrix is too soft. Generally speaking, the matrix is generally harder than the stone. If a softer matrix is used, eccentric wear is likely to occur.

4: Welding problem. When the segment is welded sideways, the saw blade will naturally wear out during the cutting process. To solve this problem, adjust the welding process.

If the front end of the segment is eccentrically worn, it is mainly due to the excessively fast cutting speed and the feeding speed, or it may be caused by insufficient diamond strength and poor grinding efficiency. When this problem occurs, the solution is to appropriately reduce the cutting speed and the feeding speed, increase the diamond strength as well.

Partial wear of saw blade segment is a very common problem. Experienced operators can judge by the cutting sound and sparks generated during the cutting process. Through different partial wear problems, different methods are used to solve them, which not only guarantees the cutting efficiency and lifespan of the saw blade segment , but also will reduce the later slab repair process, thereby reducing production costs.