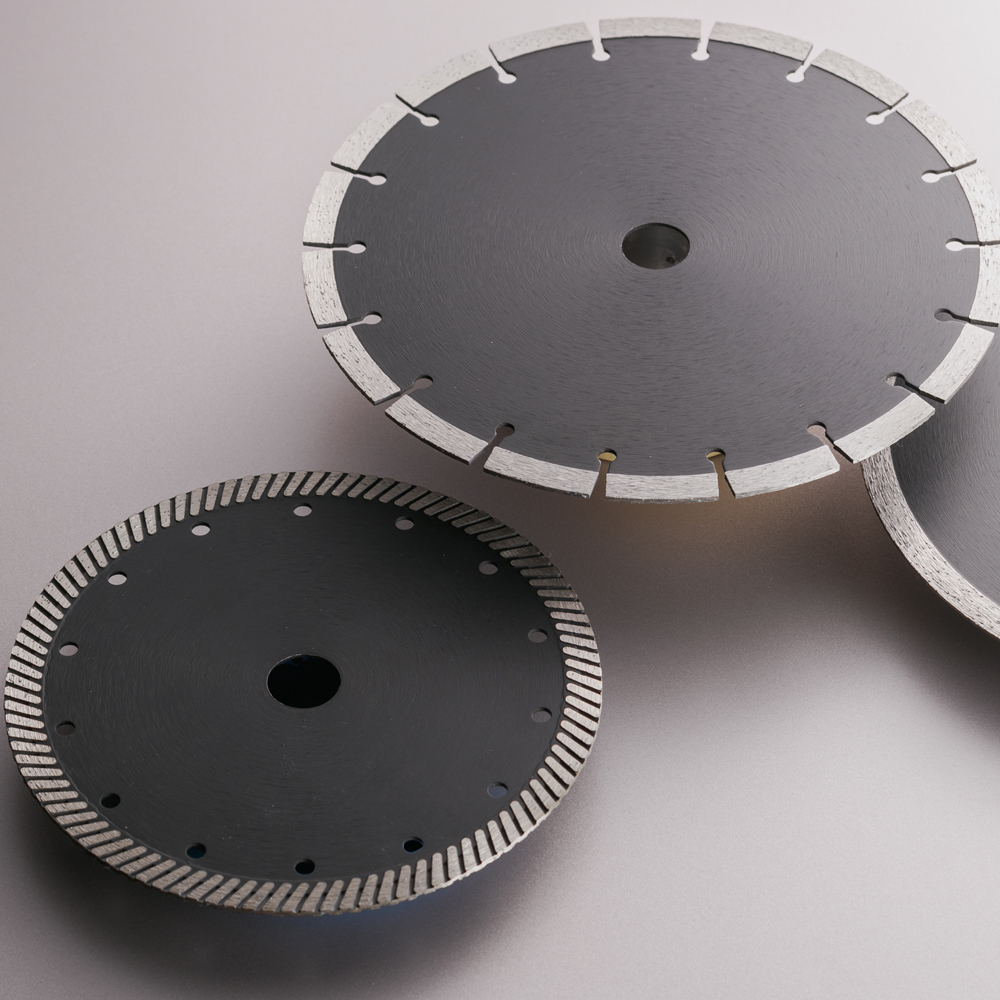

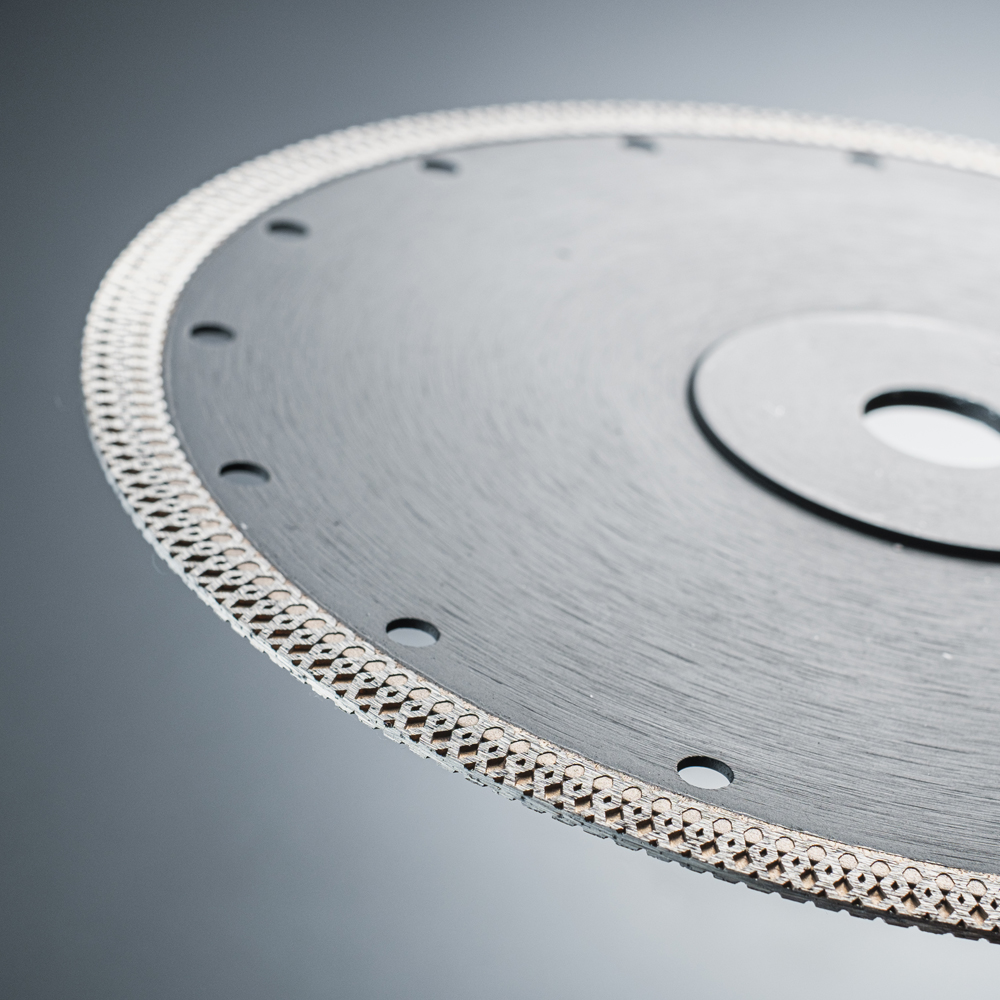

Small-diameter diamond saw blades can be used to cut hard and brittle materials such as marble, granite, concrete, refractory materials, and ceramics. The cutting equipment is generally a portable cutting machine and an angle grinder. Individual products are also used on desktop machines, such as vitrified tile saw blades, and some customers use 230mm saw blades on infrared cutting machines, which can reduce manufacturing costs. The following points should be paid attention to in the use of small diameter diamond saw blades:

The following points should be paid attention to in the use of small diameter diamond saw blades:

1. The operator should wear relevant protective equipment before operation: such as safety shoes, safety glasses, safety helmet, ear protection.

2. The cuting machine should have a protective cover or other safety device.

3. Before use, check whether the saw blade is damaged or seriously deformed. If it is damaged, it is strictly prohibited to use it.

4. Check whether there is any dirt on the chuck of the cutting machine. If there is dirt, clean it up before installing it. Whether the main shaft bearing or the main shaft or the shaft sleeve is seriously damaged, replace the new shaft sleeve or equipment when the wear is serious.

5. When installing the saw blade, the direction marked on the saw blade must be consistent with the direction of rotation of the cutting machine. Inconsistent directions can easily lead to the phenomenon of not cutting.

6. When using the saw blade for wet use, please add enough cooling water.

7. If the dry cutting saw blade is used, the dry cutting must be idle for a few seconds every 10~15 seconds to cool the saw blade. For larger cutting depths, it should be cut in steps. When the dry cutting saw blade is cooled with water, the effect will be reduced. better.

8. Curve cutting and side grinding are not allowed during the cutting process. Curve cutting and side grinding may easily cause the saw blade to crack, drop blocks or break the substrate.

9. If the cutting is oblique cutting, the depth of cut should not be too large. During the cutting process, you must pay attention to safety. Try not to let your body and the saw blade be on the same plane. If there is an abnormal sound, stop cutting immediately and check whether the saw blade is damaged, or check whether the fixing screw of the saw blade is loose.

10. If the diamond saw blade is blocked during use, the saw blade will become blunt. Please use a ceramic grinding wheel or refractory brick to re-blade (cutting a dozen knives on a ceramic grinding wheel or refractory brick), and re-opening. Sharpness can be restored after the blade.

11. When there is noise and severe vibration during the cutting process, stop immediately and check whether the saw blade has cracks or dropped blocks. When cracks and falling blocks occur, a new one needs to be replaced.

12. When cutting, the blade segment of the saw blade is more than 2mm out of the cutting material, which can reduce the edge of the material to be cut.

13. If the hole diameter of the saw blade does not match the spindle of the cutting machine, it can be matched with a suitable size washer. However, during the cutting process, it is necessary to pay attention to whether the saw blade vibrates, and if so, check whether the washer falls off. If the washer falls off and continues to be used, it is easy to cause the saw blade to vibrate when cutting, and eventually the saw blade is out of round and cannot be continued. The above problems must be paid attention to in the use of small diamond saw blades. Reasonable and correct use of small diamond saw blades will make the product last longer and the cutting effect will be improved.

The above problems must be paid attention to in the use of small diamond saw blades. Reasonable and correct use of small diamond saw blades will make the product last longer and the cutting effect will be improved.

Safe use of diamond cutting discs

Publish date:2022-11-29 13:58:15 Article From:LINSING diamond tools Clicks: