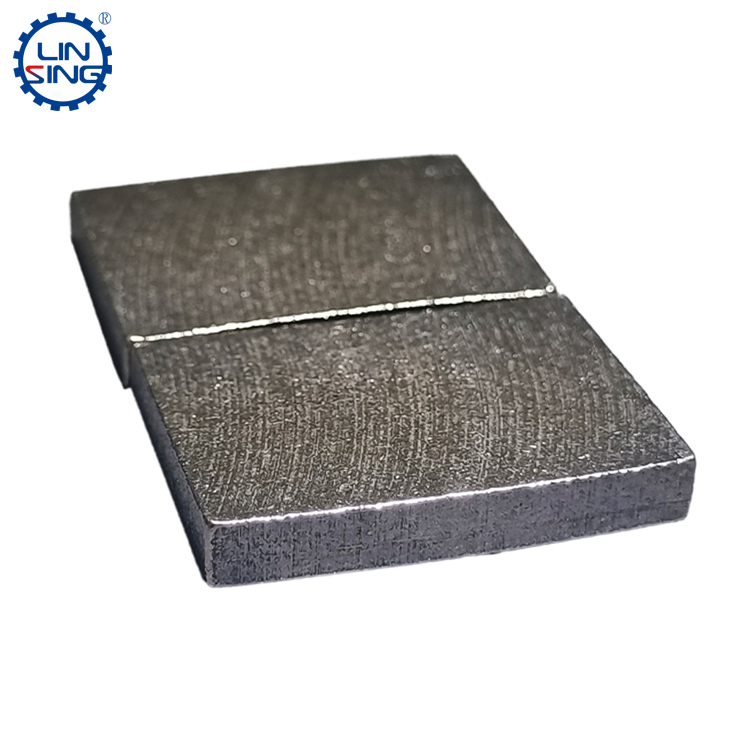

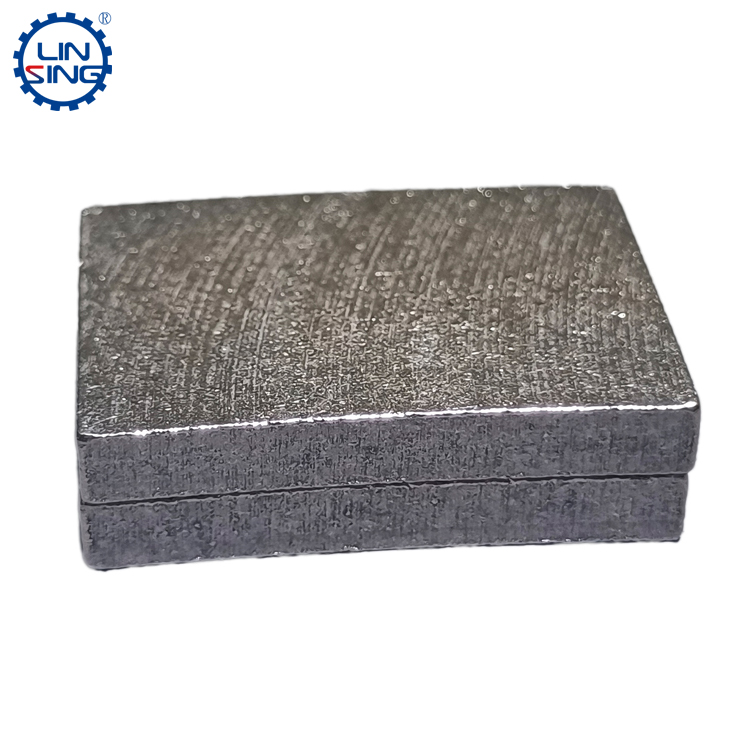

Diamond segment is made of high temperature sintering processing, the structure is relatively stable, especially in the process of cooling, the surface of the segment will generate a thin film of oxidation, to prevent further oxidation of the segment. So, in general, if the segment does not come into direct connect with water, the segment is difficult to rust again. And for most segments, if it is not cutting very expensive marble, the segment with less oxidation does not affect cutting sales and cutting life. So, what exactly should the segments be maintained? This article explains from two points in time:

First, purchase and install the maintenance of the segment:

1, Lin Xing's diamond segment is generally quadruple packaging, the outer layer is sealed with plastic tape, the middle layer is a carton packaging, and the inside is a layer of adhesive paper wrapped in a layer of plastic packaging. Such a four-layer packaging is very good to ensure that the segment will not be moisture. So, maintenance becomes very simple, that is, do not open the packaging, and placed in a dry environment to save.

2, The segment looks very strong, but the stronger things, the greater the impact force. Although we do not need to ask for light, but for some mid-path saw blade segment, it cannot be thrown at will. That is not only unsafe, and there will be segment damage, and even lead to segment deformation.

3, Try to do not touch the segment by hand. If you need to weld the segment on the substation, be sure to pay attention to the fastening nut of the fixed blade, to prevent the blade segment in use rolling.

4, Must pay attention to the arrow pointing when we installation of the segment. Do not weld the opposite direction, resulting in the use of the segment blocked.

Second, protective during the use of the segment:

1: After the segment is welded on the saw blade base, the entire blade will be very heavy, in the process of handling and moving. We must take it tender to prevent the blade from falling to the ground and tooth loss or substation bending and so on.

2: Regular maintenance of the base, testing the steel nature of the base and welding point conditions, to ensure that the base and the segment are in normal use.

3: Before cutting stone with saw blades, clean up rebar, wire and rope on mechanical or stone surfaces. If there are debris and rubble, it needs to be cleaned up in time.

4: During the use of diamond saw blades, the diamond segment may fly out at any time, so be sure to pay attention to good protective measure, wear on such as eyes production, masks, gloves, etc.

5: Good condition factory must use cooling water to cool the segment, which will better protect the segment, thus having a higher life.

The maintenance of diamond segments

Publish date:2022-07-06 19:19:43 Article From:Linsing Diamond Tools Clicks: